rock solid

SVI Trucks is a family-owned, Colorado-based company that specializes in building custom emergency vehicles. With more than 50 years in the truck manufacturing industry, our strength is in our people and our dedication to crafting the industry’s most dependable trucks. Every truck that leaves the factory is truly one-of-a-kind thanks to our innovative designs and our relentless attention to detail.

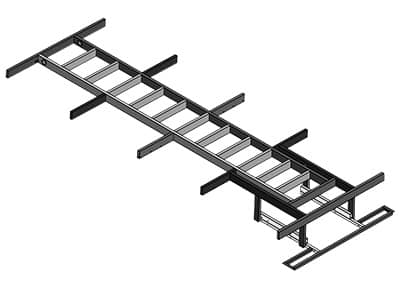

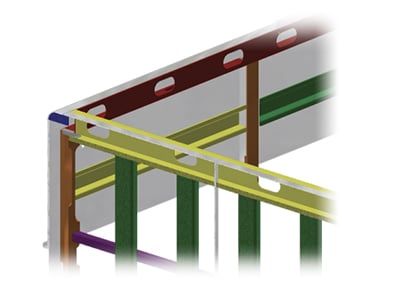

THE Strongest sub-frame

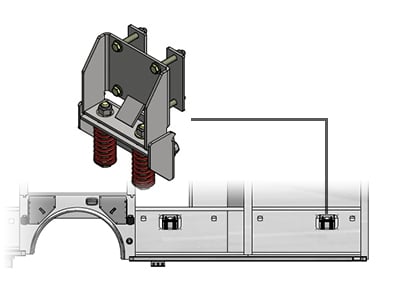

Spring-loaded mounts

Our body mounts are 1/4-inch-thick powder-coated steel assemblies that hold the chassis and sub-frame securely together with 12 3/4-inch Grade 9 bolts and heavy-duty coil springs. Our spring-mounted bodies allow for free chassis movement without transferring damaging torque into the body panels.

FORMED CROSS-SECTIONS

Unlike competitor’s stock-width aluminum extrusions, SVI Trucks’ formed-panel construction process allows for greater design flexibility. Each formed cross-section panel is custom engineered and fabricated at varying widths to accommodate your custom design while building in extra strength.

Single-wall design

SVI Trucks’ single-wall construction (between the compartments) allows for maximum usable space for the industry’s most intuitive designs. By welding the adjustable shelf track directly to the wall, we add superior strength to the design without interfering with the opening of the compartment.

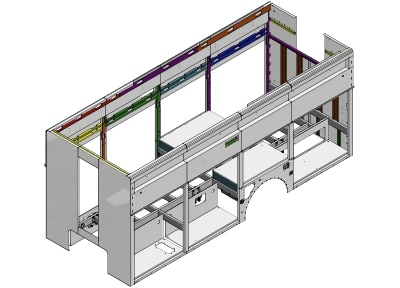

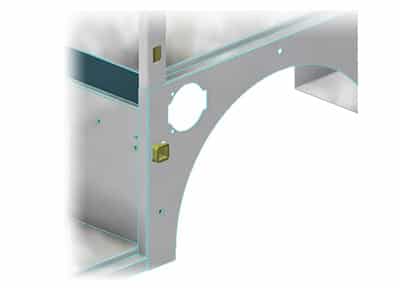

Protected Harnesses

All electrical harnesses run through formed wire raceways built into the body with main harnesses easy to access through the upper raceways. We avoid below-chassis harnesses that expose wiring to the elements, and all electrical components are grounded and accessible through the electrical panel.

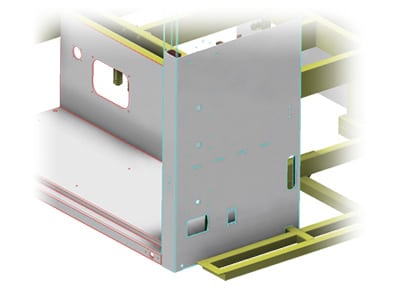

SEAMLESS REPAIRS

In the event of an accident, formed bodies don’t transfer the impact throughout the vehicle like extruded tubular construction, which in turn reduces damage. This type of body can be repaired by most heavy truck body shops without having to buy proprietary extrusions, which add extra time and cost to the process.

SUPERIOR WELDING

We continuously weld all exterior body panels and stitch weld all interior seams to give customers a truly metal-finished body. Simply put, we don’t use cover trim or glaring overlays to hide body-panel seams or connections as this kind of cover-up technique can lead to corrosion build-up behind the trim.

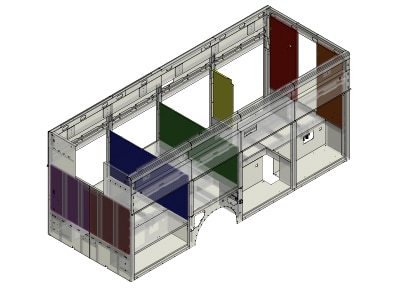

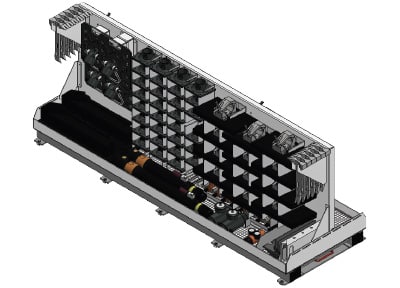

CUSTOM COMPARTMENTS

Using the latest in 3D modeling software, our engineers create computer-generated designs, right down to detailed compartment configurations. We also offer tool mounting services. Simply ship your equipment to us, or we can supply the tools for a truly turn-key fire apparatus.

All SVI Warranties are non-prorated.

SVI Trucks Recent Deliveries

Riverside County Fire Department (CA) Air/Light #1254

Clark County Fire Department (NV) Type 6 #1241-43

Medina County Sheriff’s Office, OH Command #1322R

Savannah Fire Emergency Services (GA) Air/Light #1248

Surprise Fire-Medical Department (AZ) Rescue Pumper #1282-83

Southwestern Highway 115 Fire Protection District, Colorado Springs (CO) Water Supply #1288

Lakeside Fire Protection District, El Cajon (CA) Air/Light #1271

Proliner (NY) Light Rescue #1329

Surprise Fire-Medical Department (AZ) Water Supply #1281

Durham (NC) Fire Department Walk-In Heavy Rescue #1255

Freeport LNG (TX) Light Rescues #1276 and #1277

Torrance County Fire Department, (NM) T6 Brush Truck #1290

Taos Pueblo Department of Natural Resources, Taos (NM) Type 6 Brush Truck #1284

Syracuse (NY) Walk-In Heavy Rescue #1246

Gunnison County Fire Protection District (CO) Light Rescue #1274

Gunnison County Fire Protection District (CO) Water Supply #1192

Orange Rural Fire Department (NC) Heavy Rescue #1250

CAL FIRE/Butte County Fire Department (CA) Air/Light #1266

Old Bridge Fire District 2 (NJ) Heavy Rescue #1247

Platteville-Gilcrest Fire Protection District (CO) Type 6 #1261

Lakeside (CA) Heavy Rescue #1270

Boulder County Hazmat Authority, CO Hazmat #1267

Edmonton, (AB) Walk-In Hazmat #1260

Fresno Fire Department, (CA) Hazmat #1264

Waldens Ridge Emergency Services (TN) Utility Truck #1259

Waldens Ridge Emergency Services (TN) Light Rescue #1258

Cleveland Fire Department (OH) Air/Light #1257

Gunnison County Fire Protection District (CO) Water Supply #1191

Brevard County Fire Rescue (FL) Walk-In Hazmat #1272

Dewitt Fire Department (NY) Light Rescue #1286

Topeka Fire Department, (KS) Walk-Thru Hazmat #1253

Sugar Loaf Fire Protection District, (CO) Light Rescue #1244

Rowlett Fire Department, (TX) Air/Light #1273

Fresno Fire Department, (CA) Air Rehab #1265

Central Mat-Su Fire Department (AK) Heavy Rescue #1251

Burnaby Fire Department, (BC) Twin Heavy Rescues #1238-1239

Tulare County Fire Department (CA) Light Rescue #1240-1249

South Metro (CO) Walk-In Hazmat #1235

Loveland Fire Rescue Authority, CO Rescue Pumper Fire Engine #1245

Karns Fire Department, Knoxville (TN) Heavy Rescue #1230

Stratmoor Hills FD, Colorado Springs, CO, Urban Interface Pumper #1232

Vander Fire Department, Fayetteville (NC) Heavy Rescue #1236

Fresno Fire Department, Fresno (CA) HR #1228

Upper Pine River Fire Protection District, Bayfield (CO) Water Supply #1224

Central Valley Fire District (MT) Rescue Pumper #1225-1226

Park County Fire District (WY) Light Rescue #1275

Gastonia Fire Department, Gastonia (NC) Hazmat #1231

Houston Fire Department, Houston, TX Hazmat #1237

Bargersville Community Fire Department (IN) Heavy Rescue #1229

Galeton Fire Protection District (CO) Type-3 Wildland #1222

Santa Fe Fire Rescue, Santa Fe (TX) Air/Light Unit #1233

Port Moody, BC Fire Rescue Heavy Rescue #1227

Dekalb County, GA #1206-1207 Twin Air/Light Units

Spirit Lake, IA Walk-in Medium Rescue #1221

Lexington County Fire Service, SC Walk-In Hazmat #1209

Greeley Fire Department, CO Walk-In Hazmat #1212

Elkhart Fire Department, IN Walk-Thru Heavy Rescue #1216

Barrie Fire & Emergency Services, Ontario New Hazmat Apparatus #1219

Vincennes Township Fire Department, IN, Heavy Rescue #1211

City of Miami Fire-Rescue, FL Heavy Rescue Walk-Thru #1205

City of Miami Fire and Rescue, FL Walk-In Hazmat #1204

West Metro Fire Protection District, Lakewood, CO Water Supply Unit #1194

Deer Trail, CO Fire Protection District 4×4 Urban Interface Pumper Truck #1188

Port Coquitlam, BC Fire Rescue Heavy Rescue #1208

Austin Fire Department, TX Heavy Rescue #1202

Chesterfield Township, MI Medium Rescue #1195

Campbell County Fire Department, Gillette, WY Medium Rescue Apparatus #1203

Village of Melrose (NM) Water Supply #1189

Rapids Fire Company Lockport, NY New Light Rescue #1210

Orange County Fire Authority, Irvine CA Medium Hazmat #1178

Oklahoma City, OK SVU Ventilation Unit #1220

Columbus, OH Walk-In Heavy Rescue Fleet #1196-1200

Las Vegas, NV Walk-In Hazmat Apparatus #1179

Dekalb County, GA Light Rescue Fire Truck #1201

Fountain, WV Walk-In Heavy Rescue Fire Truck #1177

Loveland Symmes, OH Refurbished Heavy Rescue #1190R

Brush, CO Rescue Pumper #1184

Earleigh Heights (MD) Walk-In Heavy Rescue #1180

Solano County, CA Utility Truck #1174

Rawlins (WY) Type 3 Wildland #1183

Farmington, NY Heavy Rescue #1175

Campbell County, WY Front Walk-In Hazmat #1173

Athens Township (MI) Heavy Rescue #1131

Boulder Rural, CO Rescue Pumper #1168

Canmore, AB (Canada) Heavy Rescue #1171

Kamloops (BC) Heavy Rescue #1167

Surprise, AZ Fire-Medical Department Pumper #1161

Surprise, AZ Fire-Medical Department Rescue Pumper #1162

Midland, TX Light Rescue (3) #1164-1166

Aurora, CO Type 6 Brush Fire Truck #1136

Aurora, CO Type 3 Wildland #1135

Crested Butte CO Light Rescue #1160

Pueblo West, CO Fire Department Hazmat #1057

Pueblo Rural, CO Fire District Hazmat #1056

Loveland Fire Rescue Authority Rescue Pumper #1159

Malaga, NJ Twp Franklin Fire District 2 Heavy Rescue #1154

Houston, TX Walk-In Rescue #1163

Ashland, KY Heavy Rescue #1152

Winnipeg, MB (CAN) Hazmat #1146